| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : YUYANG

Model Number : GY-25A

Certification : CE

Place of Origin : China

MOQ : Set/Sets

Price : US $ 3000

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 100

Delivery Time : 6

Packaging Details : 1160 x 1040 x 1320mm

Max input current : 10-70.01A

Work power : 380V 50HZ

Auto retaining time : 1-99.01S

of coolThe flow rate of cooateling wring water: 7.5L/Min 0.06-0.12Mpa : 7.5L/Min 0.06-0.120Mpa

Gross weight : Host 454.02kg Extension 43.04kg

Fluctuating frequen : 30-100.01khz

Brand : YUYANG

Output current : 200-1200A

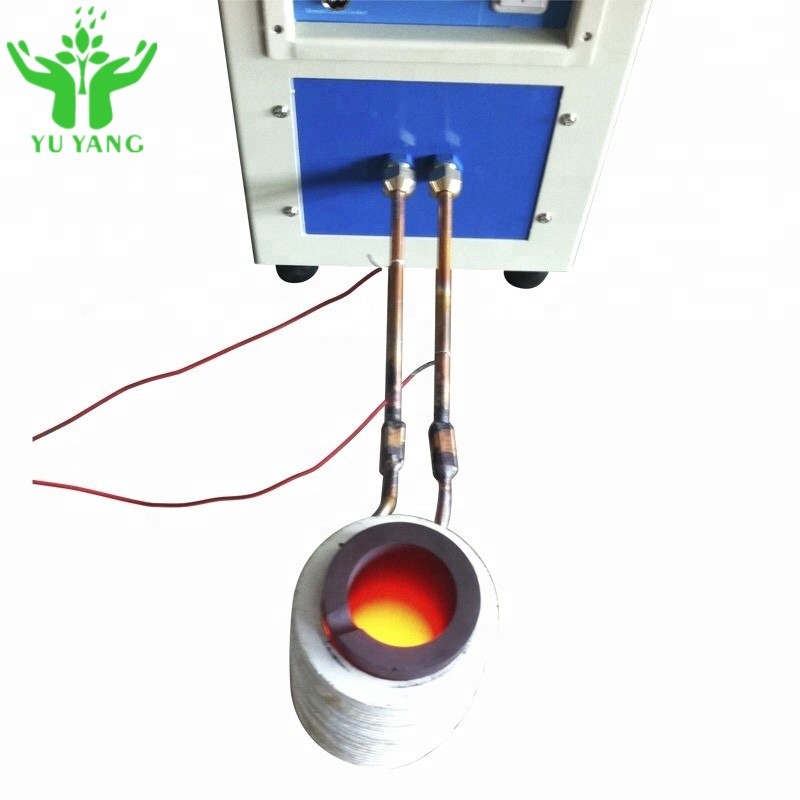

High-Efficiency Melting of Various Metals with Precise Temperature Control Testing Equipment for Different Processes

Main Applications:

1. Heat treatment of gears and shafts, ensuring enhanced mechanical properties and durability.

2. Precision brazing of diamond tools, enabling them to maintain excellent cutting performance.

3. Efficient brazing of electrical kettle bottoms.

4. Tube heating for coating purposes, facilitating the uniform application of coatings for improved protection and functionality.

5. Annealing heating of stainless steel vessels, restoring their structural integrity and improving their formability.

6. Skillful brazing of machining tools, enhancing their strength and precision for better machining results.

7. Melting of various metals, with high efficiency and precise temperature control, suitable for different metalworking processes.

8. Brazing of copper and brass tubes and connectors in air conditioner manufacturing plants, ensuring the reliable operation of air conditioning systems.

9. making the materials more malleable and facilitating the shaping process.

10. Quenching of parts to achieve the desired hardness and mechanical properties, enhancing their performance and service life.

Long Service Life Induction Heating Equipment - Reduce Maintenance Costs Compact Induction Heating Machine for Small Workshops

Parameter

| item | value |

| place of Origin | China |

| Brand Name | YUYANG |

| Condition | New |

| Machine Type | Induction Heating Machine |

| Machinery TestReport | Provided |

| Marketing Type | New Product 2021 |

| Warranty of core components | 1 Year |

| Core Components | PLC, Motor |

| Warranty | 1 Year |

| Key Selling Points | Easy to Operate |

| After Warranty Service | Video technical support, Online support |

| Local Service Location | Malaysia, Saudi Arabia, Pakistan, India |

| Applicable Industries | Machinery Repair Shops, Manufacturing Plant, Other |

| Showroom Location | None |

| Rated Power output | 60kw |

| Work power | 340V-430V |

| Maximum input cur | 10-70A |

| Volume(mm 3) | 660 mmx290mmx410mm 740 mmx340mmx380mm |

| Max input current | 200-1200A |

| Gross weight | Host 54kg Extension 43kg |

| Power supply | Three phase 380v 50Hz |

| Time sting(atomatic time) | 1-99.02s |

| Cooling water | 0.08-0.16MPa 9L/min |

Operating Principle

Frequency conversion electromagnetic induction heating or induction heating for short is a method for heating metal

materials by converting power frequency power supply into that of specific range based on the principle of electromagnetic

induction. This type of heating technique is also applicable to packing industry (such as sealing of aluminum foil used in medicine and food industry), semiconductor material .

Basic components of induction heating system include induction coil, AC power source and work pieces.

Induction coil can be fabricated into different shapes as per different heated objects. The coil is connected with the power source providing alternating current for coil.

Advantages of Induction Heating Equipment

1. Rapid Heating: The minimum heating time is under 1 second, and the heating rate is adjustable and controllable.

2. Broad Heating Application: Suitable for heating various metal parts. You can replace the removable induction coil according to different operation requirements.

3. Simple Installation: Just connect it to the power source, induction coil, water supply pipe, and return pipe, and it's ready to use. It is compact in size and lightweight.

4. User-friendly Operation: You can master its operation within a few minutes.

5. Quick Start-up: It can start heating immediately as long as water and power are available.

6. Low Power Consumption: Compared with traditional vacuum tube high-frequency equipment, it can save about 70% of the power. Smaller workpieces consume even less power.

7. High Efficiency: It features uniform heating (you can adjust the spacing of the induction coil to ensure the proper temperature for each part of the workpiece), rapid warming, and a limited oxidation layer, preventing any post-annealing waste.

8. Comprehensive Protection: Equipped with functions like overpressure, overcurrent, overheat, and water shortage alarm indications, along with automatic control and protection.

9. Precise Temperature Control: You can control the heating temperature of workpieces according to the preset heating time, thus maintaining the temperature at a specific technical level.

10. Full Load Design: Capable of continuous 24-hour operation.

|

|

High Efficiency Melting Of Various Metals With Precise Temperature Control Testing Equipment For Different Processes Images |